Metallkreissägeblätter

Unsere Metallkreissägeblätter für Kreissägemaschinen (Typensägen) sind allesamt dampf angelassen. Diese Ausführung optimiert den Trennvorgang durch noch höhere Schnittleistung, schützt gegen Spanaufschweißung und ermöglicht eine bessere Aufnahme des Kühl- und Schmiermittels.

Material, Qualitäten und Einsatzbereiche

Nachfolgend sind unsere zwei Qualitäten aus Schnellarbeitsstahl aufgeführt:

GUHEMA Super-HSS

GUHEMA Super-HSS

DMo 5 Qualität (Werkstoff-Nr. 1.3343)

DMo 5 Qualität (Werkstoff-Nr. 1.3343)

Das Werkstattblatt

Das Werkstattblatt

GUHEMA Brillant

GUHEMA Brillant

EMo 5 Co 5 Qualität (Werkstoff-Nr. 1.3243)

EMo 5 Co 5 Qualität (Werkstoff-Nr. 1.3243)

Für nicht rostende Stähle

Für nicht rostende Stähle

Fühlen Sie uns auf den Zahn

Wenn perfektes Trennen angestrebt ist, müssen alle Faktoren optimal aufeinander abgestimmt sein. Die Zahnform spielt dabei eine bedeutungsvolle Rolle. Ihnen stehen folgende Zahnformen zur Verfügung, die nach DIN 1840 gefertigt werden:

Bogenzahn mit Wechselschliff (BW)

Wir empfehlen den Bogenzahn mit Wechselschliff bei Metallkreissägeblättern bei einer feinen Zahnteilung zum Sägen von Rohren oder Profilen.

Bogenzahn mit Vor- und Nachschneider (HZ)

Der Bogenzahn mit Vor- und Nachschneider ist für das Sägen von Stählen auf Sägemaschinen und Rundtaktautomaten geeignet und empfiehlt sich bei mittleren und groben Zahnteilungen.

Produkte

GUHEMA Super-HSS

OSD...

GUHEMA Super-HSS

OSD...

DMo 5 Qualität (Werkstoff-Nr. 1.3343)

DMo 5 Qualität (Werkstoff-Nr. 1.3343)

Das Werkstattblatt

Das Werkstattblatt

GUHEMA Brillant

OSE...

GUHEMA Brillant

OSE...

EMo 5 Co 5 Qualität (Werkstoff-Nr. 1.3243)

EMo 5 Co 5 Qualität (Werkstoff-Nr. 1.3243)

Für nicht rostende Stähle

Für nicht rostende Stähle

Der schnelle Weg zu unserer Artikel-Nr.

Qualität + Kennziffer 1 + Kennziffer 2 + Kennziffer 3

z.B.:

OSD + 3205 + G + BH = OSD3205GBH

| Ø / Stärke / Bohrung | Kennziffer 1 | BW | BW | HZ | HZ | BW | HZ | HZ | HZ | HZ | HZ | NL | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in mm | 3 mm | 4 mm | 5 mm | 6 mm | 7 mm | 8 mm | 9 mm | 10 mm | 12 mm | 14 mm | in mm | |||

| 200 | 1,75 | 32 | ...3205... | 200 | 160 | 128 | 100 | AD | ||||||

| 225 | 2,0 | 32 | ...4225... | 220 | 180 | 150 | 120 | 90 | AD | |||||

| 2,0 | 40 | ...4229... | 220 | 180 | 150 | 90 | BH | |||||||

| 250 | 2,0 | 32 | ...4255... | 240 | 200 | 160 | 128 | 100 | 80 | AD | ||||

| 2,0 | 40 | ...4259... | 240 | 200 | 160 | 128 | 100 | 80 | BH | |||||

| 2,5 | 32 | ...5255... | 200 | 160 | 128 | 100 | AD | |||||||

| 2,5 | 40 | ...5259... | 200 | 160 | 120 | 100 | BH | |||||||

| 275 | 2,0 | 32 | ...4275... | 220 | 180 | 144 | 110 | AD | ||||||

| 2,0 | 40 | ...4279... | 280 | 220 | 180 | 144 | 110 | BH | ||||||

| 2,5 | 32 | ...5275... | 220 | 180 | 144 | 110 | AD | |||||||

| 2,5 | 40 | ...5279... | 280 | 220 | 180 | 144 | 120 | 110 | 96 | 84 | 72 | BH | ||

| 3,0 | 40 | ...6279... | 220 | 180 | 144 | 120 | 110 | BH | ||||||

| 300 | 2,5 | 32 | ...5305... | 240 | 200 | 160 | 120 | 100 | AD | |||||

| 2,5 | 40 | ...5309... | 240 | 200 | 160 | 120 | 100 | BH | ||||||

| 315 | 2,5 | 32 | ...5315... | 250 | 200 | 160 | 120 | AD | ||||||

| 2,5 | 40 | ...5319... | 250 | 200 | 160 | 120 | 100 | 80 | BH | |||||

| 3,0 | 32 | ...6315... | 250 | 200 | 160 | 120 | AD | |||||||

| 3,0 | 40 | ...6319... | 250 | 200 | 160 | 120 | 100 | 80 | BH | |||||

| 350 | 3,0 | 32 | ...6355... | 280 | 220 | 180 | 140 | 110 | AD | |||||

| 3,0 | 40 | ...6359... | 280 | 220 | 180 | 140 | 110 | BH | ||||||

| 400 | 3,5 | 40 | ...7409... | 200 | 160 | 128 | 100 | 80 | FHB | |||||

| 3,5 | 50 | ...7404... | 180 | 160 | 140 | 128 | 100 | I | ||||||

Kennziffer 2

Legende Zähnezahl

| BW | HZ | ||

|---|---|---|---|

| 160 = ...Q... | 72 = ...A... | 120 = ...H... | 200 = ...O... |

| 180 = ...R... | 80 = ...B... | 128 = ...I... | 220 = ...P... |

| 200 = ...S... | 84 = ...C... | 140 = ...J... | 270 = ...Ü... |

| 220 = ...U... | 90 = ...D... | 144 = ...K... | 280 = ...X... |

| 240 = ...V... | 96 = ...E... | 150 = ...L... | 300 = ...Y... |

| 250 = ...W... | 100 = ...F... | 160 = ...M... | 340 = ...Z... |

| 280 = ...X... | 110 = ...G... | 180 = ...N... |

Kennziffer 3

Legende Nebenlöcher

| 2/8/45 = ...A... |

| 2/8/55 = ...B... |

| 2/9/50 = ...C... |

| 2/11/63 = ..D.... |

| 2/12/64 = ...E... |

| 2/15/80 = ...F... |

| 4/9/50 = ....G.. |

| 4/12/64 = ...H... |

| 4/15/80 = ...I... |

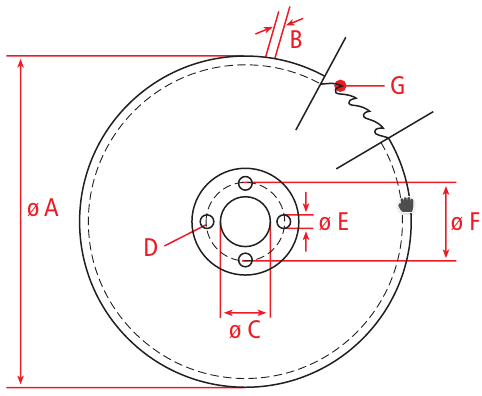

Bei der Bestellung machen Sie bitte folgende Angaben:

- Artikelnummer

- Andere Abmessungen bieten wir an, nennen Sie uns:

- A Durchmesser des Blattes

- B Blattstärke

- C Hauptbohrung

- D Anzahl der Nebenlöcher

- E Lochdurchmesser

- F Teilkreis der Nebenlöcher

- G Zahnteilung oder Zähnezahl