Maschinensägeblätter

Wir geben Ihnen die Garantie, dass Sie mit einem Sägeblatt, das den Namen GUHEMA trägt, ein Spitzenprodukt der Zerspanungstechnologie erwerben. Der adäquate Nutzen für Ihren Produktionsablauf und die hohe Lebensdauer von Sägeblatt und Maschine wird auch im permanenten, harten Dauereinsatz gewährleistet.

Material, Qualitäten und Einsatzbereiche

Unser Streben nach perfekter Sägequalität beginnt schon bei der Auswahl unseres Vormaterials, denn dies ist die Ausgangsbasis für unsere Spitzenprodukte – nichts geht durch unsere Eingangskontrolle, das nicht die Note „Sehr gut“ verdient.

Erstklassiges Rohmaterial ist bei GUHEMA die Basis für präzises, schnelles und wirtschaftliches Sägen mit

- hohen Stand- und kurzen Schnittzeiten

- langer Lebensdauer

- optimaler Schonung Ihrer Sägemaschine

Für die unterschiedlichsten Einsatzbereiche führen wir die passenden Qualitäten

GUHEMA Super-HSS

GUHEMA Super-HSS

DMo 5 Qualität (Werkstoff-Nr. 1.3343)

DMo 5 Qualität (Werkstoff-Nr. 1.3343)

Für Werkstoffe bis zu einer Zugfestigkeit von 1100 N/mm2

Für Werkstoffe bis zu einer Zugfestigkeit von 1100 N/mm2

GUHEMA Brillant

GUHEMA Brillant

EMo 5 Co 5 Qualität (Werkstoff-Nr. 1.3243)

EMo 5 Co 5 Qualität (Werkstoff-Nr. 1.3243)

Für extrem harte Werkstoffe bis 1300 N/mm2 z.B. austenitische Stähle und Stähle mit hohem Chrom-Nickelgehalt

Für extrem harte Werkstoffe bis 1300 N/mm2 z.B. austenitische Stähle und Stähle mit hohem Chrom-Nickelgehalt

GUHEMA Bi-lastic

GUHEMA Bi-lastic

DMo 5 Schneidenqualität (Werkstoff-Nr. 1.3343) auf einem Sonderstahlrücken

DMo 5 Schneidenqualität (Werkstoff-Nr. 1.3343) auf einem Sonderstahlrücken

Für Werkstoffe bis zu einer Zugfestigkeit von 1100 N/mm2

Für Werkstoffe bis zu einer Zugfestigkeit von 1100 N/mm2

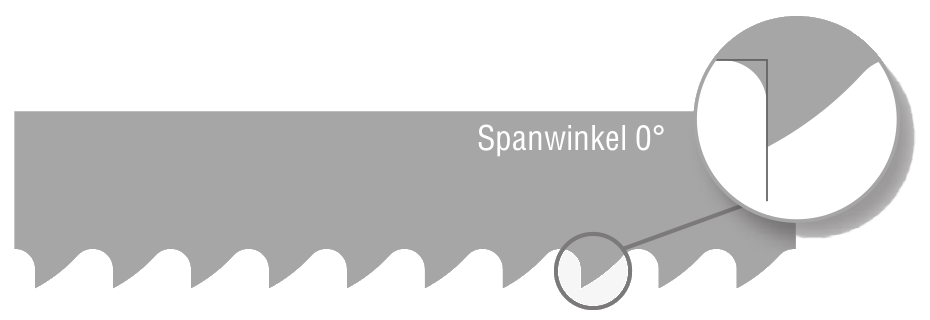

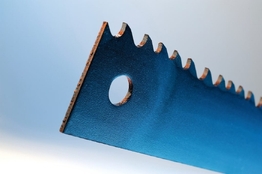

Die Wahl der richtigen Zahnform

Unsere GUHEMA-Maschinensägeblätter haben erst durch die richtige Zahnform den optimalen Biss. Wir liefern: