Metallsägebänder

Wir geben Ihnen die Garantie, dass Sie mit einem Sägeband, das den Namen GUHEMA trägt, ein Spitzenprodukt der Zerspanungstechnologie erwerben. Den adäquaten Nutzen für Ihren Produktionsablauf und die hohe Lebensdauer von Sägeband und Maschine wird auch im permanenten, harten Dauereinsatz gewährleistet.

Sägebänder aus Werkzeugstahl

Werkzeugstahl (125 Cr 1)

- Zahngehärtetes Sägeband

- Für unlegierte Stähle bis zu mittleren Festigkeiten

NC20... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE20... = fertig geschweißt

NE20... = fertig geschweißt

Werkzeugstahl (125 Cr 1)

- Zahn- und Rückengehärtetes Sägeband

- Für Bau-, Automaten- und Einsatzstähle

- Werkstattmeister

NC22... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE22... = fertig geschweißt

NE22... = fertig geschweißt

Sägebänder aus Bi-Metall

M42 Qualität (Werkstoff-Nr. 1.3247)

- Für Profile und Rohre im Bündelschnitt

- Die Spezialschränkung verhindert ein Verklemmen des Sägebandes während des Schnittprozesses

NC33... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE33... = fertig geschweißt

NE33... = fertig geschweißt

NC34... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE34... = fertig geschweißt

NE34... = fertig geschweißt

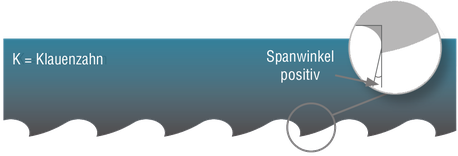

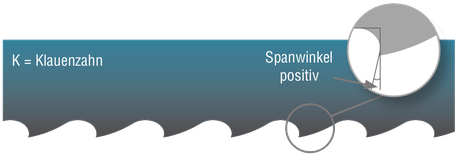

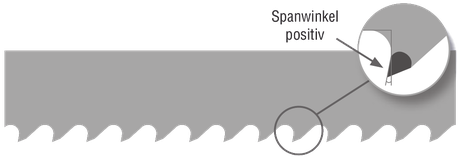

M42 Qualität (Werkstoff-Nr. 1.3247)

- Verschleißfeste Zahnspitzen aus M42

- Besonders für dünne bis mittlere Werkstücke geeignet

NC35... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE35... = fertig geschweißt

NE35... = fertig geschweißt

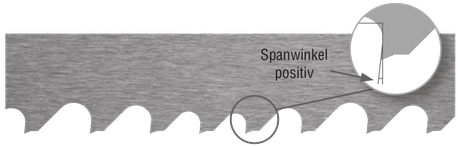

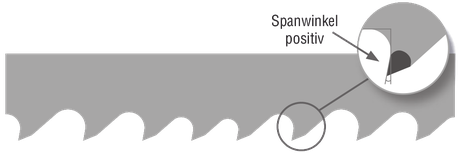

M42 Qualität (Werkstoff-Nr. 1.3247)

- Verschleißfeste variable Verzahnung aus M42

- Besonders für schwingungsreduziertes Sägen von dünnen bis mittleren Werkstücken geeignet

NC35... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE35... = fertig geschweißt

NE35... = fertig geschweißt

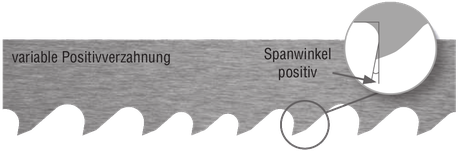

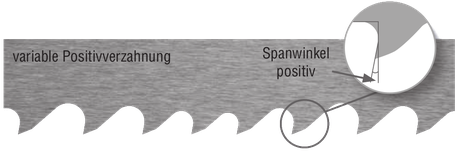

M42 Qualität (Werkstoff-Nr. 1.3247)

- Verschleißfeste variable Positivverzahnung aus M42

- Besonders für schwingungsreduziertes Sägen von mittleren bis großen Werkstücken geeignet

- Hohe Zerspanleistung und lange Lebensdauer

NC35... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE35... = fertig geschweißt

NE35... = fertig geschweißt

M51 Qualität (ähnlich Werkstoff-Nr. 1.3207)

- Extrem verschleißfeste variable Positivverzahnung aus M51

- Bestens für schwingungsreduziertes Sägen von mittleren bis großen Werkstücken geeignet

- Deutlich höhere Standzeit/Schnittgeschwindigkeit gegenüber der M42 Qualität (GUHEMA No. 35 VP Bi-Co-lastic)

- Eignet sich für schwer zerspanbare Werkstoffe

NC36... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE36... = fertig geschweißt

NE36... = fertig geschweißt

Sägebänder besetzt mit Hartmetall

Chromlegiertes Trägerband besetzt mit Hartmetallgranulat

- Für Abrasiv- und Verbundwerkstoffe

- Besonders geeignet für Kabel und Drähte, Keramik, Fiberglas sowie Reifen

- Punktet dort, wo Sägezähne von Nachteil sind

NC40... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE40... = fertig geschweißt

NE40... = fertig geschweißt

Chromlegiertes Trägerband besetzt mit Hartmetallgranulat

- Für Abrasiv- und Verbundwerkstoffe

- Besonders geeignet für Kabel und Drähte, Keramik, Fiberglas sowie Reifen

- Punktet dort, wo Sägezähne von Nachteil sind

- Das unterbrochene Sägeband sichert den Spanabtransport auch bei großem Spanaufkommen

NC41... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE41... = fertig geschweißt

NE41... = fertig geschweißt

Chromlegiertes Trägerband besetzt mit Hartmetallzähnen

- Geschränktes, hartmetallbesetztes Sägeband

- Der Einstieg in die Hartmetallsägebandtechnologie

- Zerspant sicher versandete Gusswerkstücke

- Erzielt deutlich höhere Standzeiten gegenüber einem Sägeband aus Bi-Metall

NC45... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE45... = fertig geschweißt

NE45... = fertig geschweißt

Chromlegiertes Trägerband besetzt mit Hartmetallzähnen

- Geschliffenes, hartmetallbesetztes Sägeband

- Die geschliffenen Sägezähne mit Vor- und Nachschneider ermöglichen höchste Standzeiten und Schnittgeschwindigkeiten

- Hergestellt für schwer zerspanbare Werkstoffe und versandete Werkstücke

NC46... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE46... = fertig geschweißt

NE46... = fertig geschweißt

Chromlegiertes Trägerband besetzt mit Hartmetallzähnen

- Geschliffenes, hartmetallbesetztes Sägeband

- Die geschliffenen Sägezähne mit Vor- und Nachschneider ermöglichen höchste Standzeiten und Schnittgeschwindigkeiten

- Spezialzahnform für die Bearbeitung von extrem harten Werkstücken wie z.B. randschichtgehärtete Wellen

NC47... = Rollenware von 30,5 Meter oder Fabrikationsrollen

NE47... = fertig geschweißt

NE47... = fertig geschweißt